Developed Process Technology

Blunging

The China Clay (kaolin) is mixed with water to create milk-shake-like slurry. Slurry is simply the water and dispersed clay mixture, which puts the clay particles in suspension.

De-gritting

The slurried China Clay (kaolin) is usually transported through pipelines to degritting facilities, where sand, mica and other impurities are extracted with the help of gravity.

Solid-Liquid Separation

We feed 35-40% solid concentration slurry in to the filter press by stroke pumps to separate water out of slurry. Due to stickiness of the clay we go up to 8 kg/cm2 pressure. After formation of clay cake the moisture content varies from 20-25%.

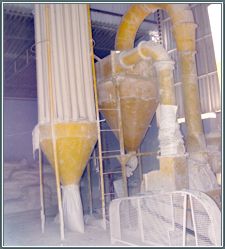

Drying

The wet cake having moisture 8 – 12% comes in contact with hot drying air in the cage mill & gets conveyed to cyclone through dryer flash ducts & the drying takes place in cage mill & flash duct. Water evaporation is around 8 % to 10%. Final product is around 1 – 1.5% moisture & size is granules cum powder.The dried material gets conveyed to cyclone separator & discharge through rotary airlock valve in the form of dried granules cum powder. This granules cum powder are then passed through pulverizer to make it powder as required.The fines are passed on to bag filter & are discharged through rotary air lock valves.

Filtering and Brightness enhancement

With both the fine and coarse China Clay (kaolin) particle fractions, brightness is enhanced through one or move processes which will remove iron, titanium, organic, and other undesirable materials.

Powdering and Packing

After Sun drying we break the cakes in to small sizes max 5” or powder as per the requirement of customer.

We make powder by hammer grinding mill.